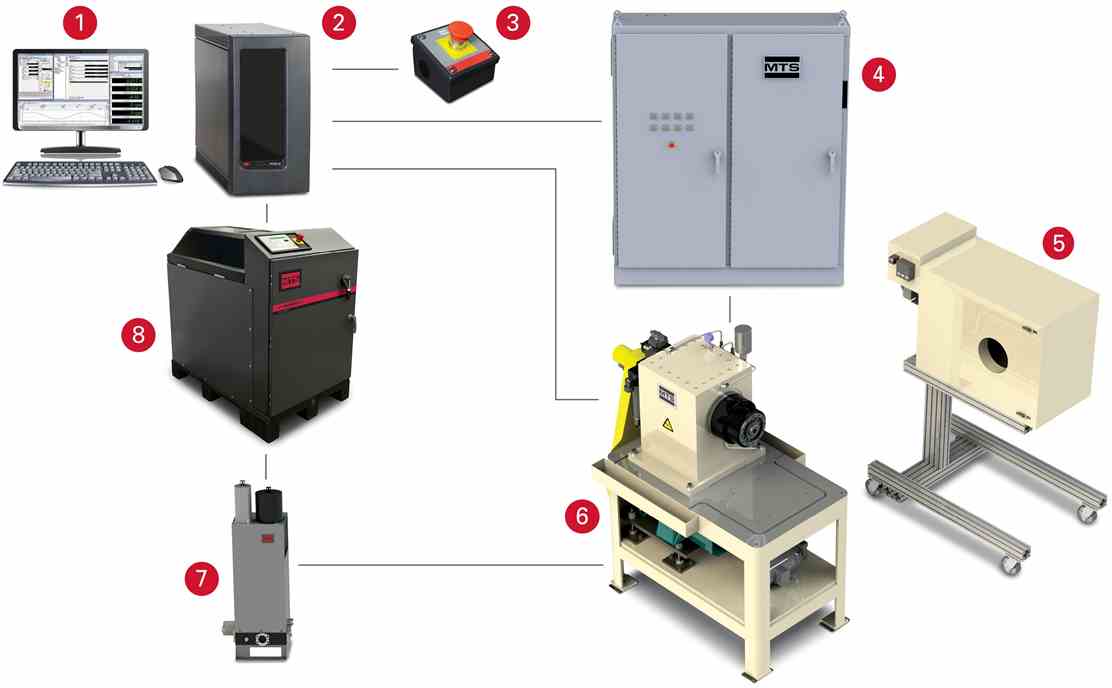

Replicate a broad range of real-world engine torsional vibration phenomena to analyze, evaluate and validate the damping and vibration in automotive clutch systems. Designed to accommodate both manual and automatic transmissions, the Model 814 can be configured for testing clutch dampers, entire clutch assemblies and front-end accessory drive components.

FlexTest digital controls and MTS transducers combine to provide precision control and monitoring of angular displacement, acceleration and torque

Employs an advanced spinning torsional actuator to apply real-world engine vibrations to clutch systems and components

Covers a broad range of torque and speed requirements to test clutch dampers, assemblies and accessories for both automatic and manual transmissions

Available in compact bench or easy-to-setup and access platform styles

| Torque | Dynamic Angular Displacement | Static Angular Displacement | Speed |

| 1500 N·m | 135 +/- deg | 140 +/- deg | 7000 rpm |

| 2000 N·m | 65 +/- deg | 70 +/- deg | 7000 rpm |

| 3000 N·m | 65 +/- deg | 70 +/- deg | 7000 rpm |

| 4500 N·m | 45 +/- deg | 50 +/- deg | 4000 rpm |

Model 814 systems are available in compact bench or easy-to-access platform styles: